Commitment to Quality

Commitment to Quality

Pursuit of the world's highest quality

We have inherited the experience and the expertise gained over our 60-year history, and remain committed to our mission and providing the world’s best quality.

Demonstration testing of new technology and materials

We are equipped with a variety of industrial testing facilities. We constantly strive to improve product quality by conducting tests to verify the reliability of cutting-edge technology and materials, and by using the best manufacturing methods and materials.

DAIKAN Test FacilitiesCustomer-centric approach

We always prioritize our customers’ needs first and strive to exceed their expectations. We believe that improving quality directly leads to increased customer satisfaction.

"To meet your needs for safe and durable signage."

Weather Meter

We take a scientific approach to developing better products, and that means testing, testing and even more testing. So it goes without saying that we have a full suite of Weatherability testing equipment at our factory. Here are some of the machines we use:

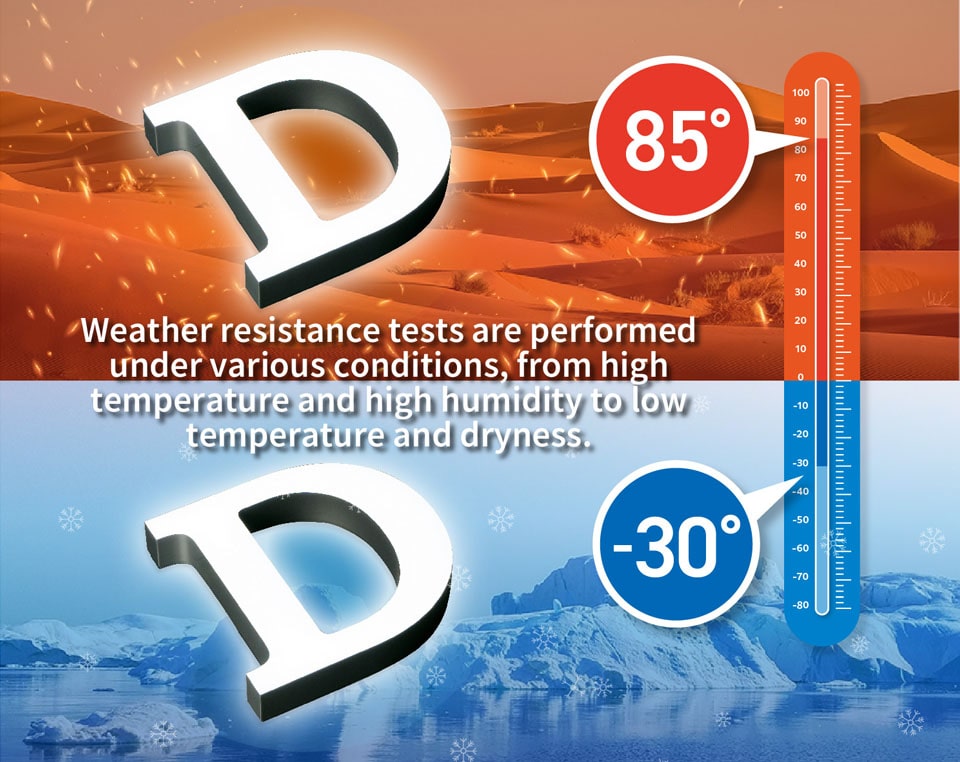

Low Humidity Type Temperature and Humidity Chamber

We test for deformation of materials and finished products under different heat and humidity conditions.

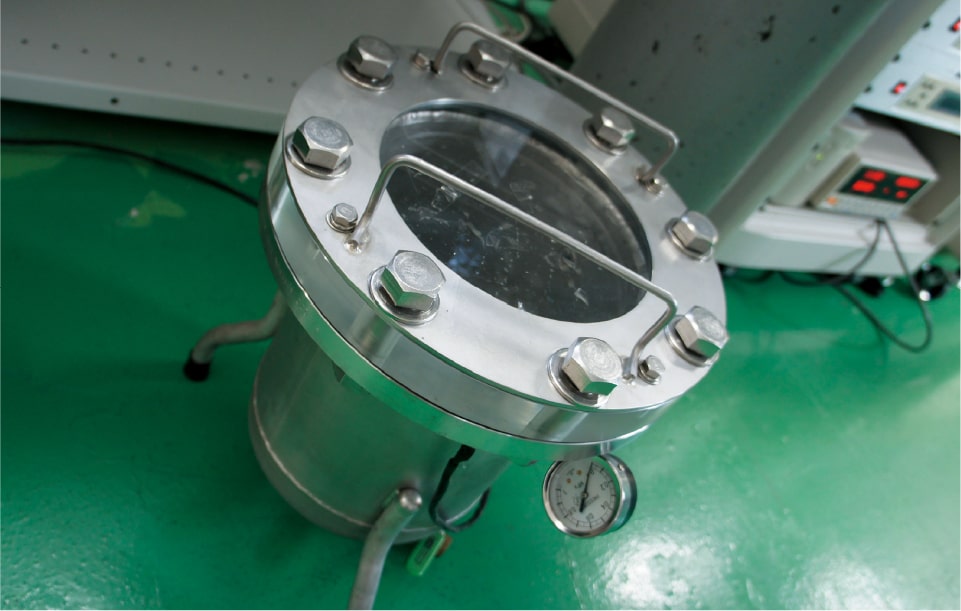

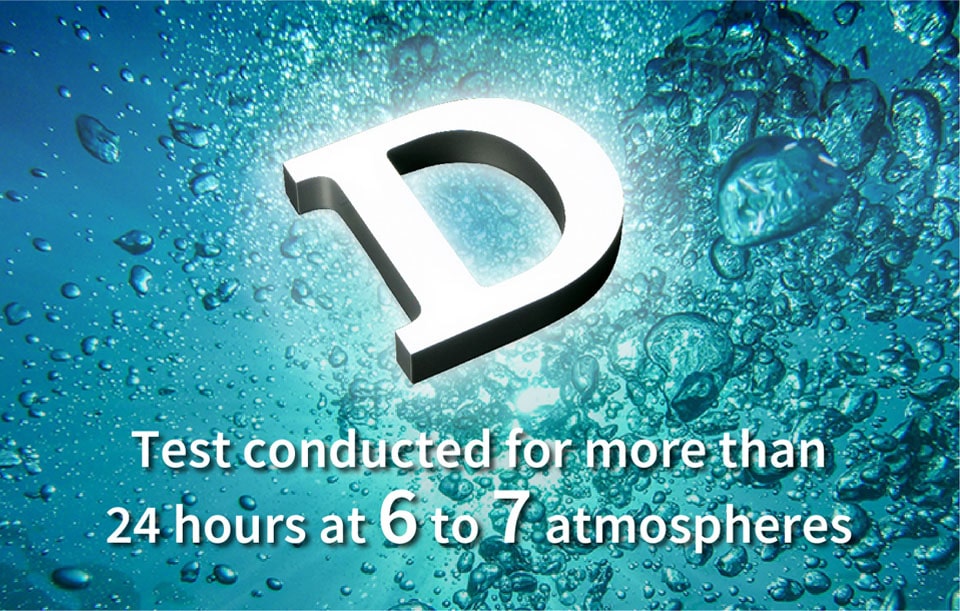

High-Pressure Type Water Resistance Tester

With this machine we test waterproof qualities of our products which are aimed for outdoor and underwater usage. It allows applying maximum pressure of 10kgf/cm2 on testing materials.

-

Super Xenon Weather Meter

This is used to test signage under near-natural environments with arc xenon lamp and spray recycling.

-

Combined Cyclic Corrosion Test Instrument

This machine helps test corrosion prevention and durability of top coatings, painting and plating finishes of signs.

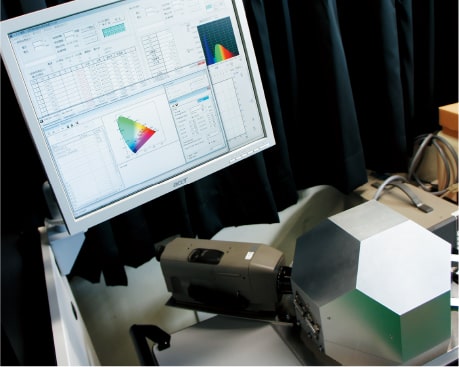

Optical Characteristic Inspection System

Our light measurement system with integrating sphere and luminance colorimeter allows testing specifications (illuminance, luminous flux, luminance, chromaticity, color temperature, color rendering index, wavelength) of various LED types with high precision.

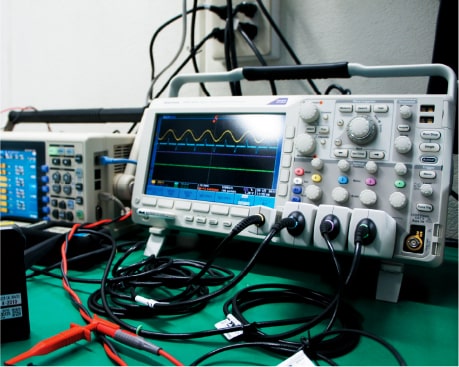

Electrical Characteristic Inspection

We conduct performance evaluation for one-off circuit board, LED module and AC/DC Power Supply with Oscilloscope and Power Analyzer which allow us to make precise measurements and analysis in a short time.

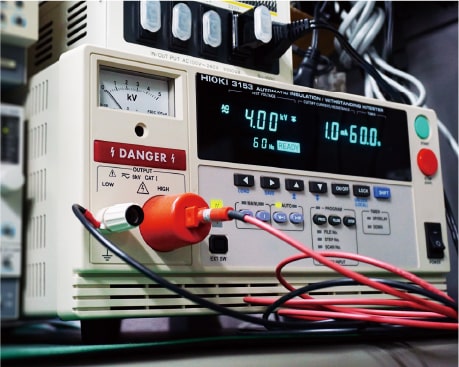

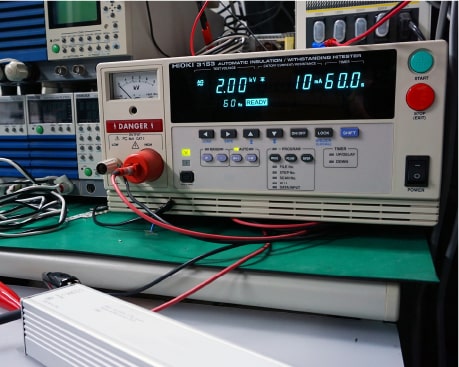

Electric Strength Test

An electric safety testing machine was introduced to conduct insulation and pressure tests on all electric components and products. The purpose of conducting these tests is to check the sufficient insulation performance of our products in order to protect users from any risk of electric shock or fire.

Surface Observation and Evaluation

With the use of spectrophotometer, digital variable gloss meter and digital microscope we conduct accurate evaluation by thoroughly observing changes on the weatherability-tested product surface and quantifying the facts.